| View previous topic :: View next topic |

| Author |

Message |

foss0194

Member

Joined: Mar 18, 2017

Posts: 30

|

Posted: Tue Jan 09, 2018 11:34 am Post subject: Got a points problem! and Starter Question Posted: Tue Jan 09, 2018 11:34 am Post subject: Got a points problem! and Starter Question |

|

|

Recently changed guts out of distributor, replaced spark plug wires, and plugs.

Engine hesitates, sputters, and backfires at higher RPM's. Low RPM's you can hear a little extra air intermittently out of the exhaust.

Replaced points, properly gaped, and did timing. Runs great for little while, but less than a tank of fuel later starts doing it all again. Third time adjusting points and twice have replaced points.

Any ideas?

Have M38 with 24V system and original motor.

Don't think related, but my starter turns very slow....like batteries are dead. Batteries are both fully charged. Is that normal for original parts or is the starter dying? |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16365

Location: Wisconsin

|

Posted: Tue Jan 09, 2018 2:58 pm Post subject: Posted: Tue Jan 09, 2018 2:58 pm Post subject: |

|

|

With distributor there are several things to check.

1-Is the terminal connection on the point plate at the points properly insulated. Sometimes this small insulator gets damaged.

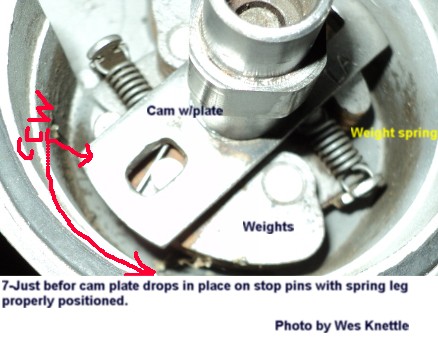

2-Are your mechanical advance (Governor) weights free to travel and spring back properly? A quick check you rotate the distributor rotor against normal travel (advanced) and it should move freely 10 Degrees or so and when you release the rotor it should snap back to it's original position quickly.

3-Have you checked your condenser and the radio noise filter capacitor with a proper capacitor/condenser tester or at least substituted know good ones. These can often have their resistances varied too much by heat.\

4-Have you checked the primary & secondary resistance (in OHMs) of your coil both cold & hot? By hot I mean uncomfortable to touch hot. You can heat the coil with a hair dryer. If there is a significant difference in readings Hot vs Cold then substitute a known good coil.

Slow starters are caused by:

1-Poor or missing grounds. The ground strap should be installed at the right front engine mount. The contact area of the face of the starter and the seat area on the bell housing should be paint free. Bolts should be clean and contact areas on both the bell and the starter paintless. The battery terminals must be clean, corrosion free and tight. Again check for clean paint free contact surfaces.

2-Worn brushes.

3-Loose bearings

4-Damages or overheated armature/commutator.

Be sure to use the extracts of TM 9-1825B dated 1952 for troubleshooting these items. The applicable chapters are available in PDF on our downloads page.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

foss0194

Member

Joined: Mar 18, 2017

Posts: 30

|

Posted: Tue Jan 09, 2018 3:28 pm Post subject: Posted: Tue Jan 09, 2018 3:28 pm Post subject: |

|

|

| Thanks you!! |

|

| Back to top |

|

|

foss0194

Member

Joined: Mar 18, 2017

Posts: 30

|

Posted: Thu Feb 08, 2018 2:37 pm Post subject: Posted: Thu Feb 08, 2018 2:37 pm Post subject: |

|

|

Checked all grounding. Found potential loose ground in distributor. Replaced condenser and coil. Extra insulated wiring inside distributor. Found float in carb slightly out of adjustment.

Running great currently, however noticing some "white film" accumulating on points. Not "burned", but causing problems cited in first post. Quick file on points and it starts running great again. Starts right up.

2 questions:

1. Does this extra info help diagnosis what may be causing the points to prematurely become "fouled"?

2. Is there a resistor for the distributor/in the distributor to drop the voltage to the points? Getting 24 volts on both sides of the coil. Have looked through the site and cannot find schematic for the 24 volt waterproof distributor. |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16365

Location: Wisconsin

|

Posted: Tue Feb 13, 2018 11:31 am Post subject: Posted: Tue Feb 13, 2018 11:31 am Post subject: |

|

|

Do you have the distributor properly vented thru the vent system? It needs that to unload the ionized gasses. Which will promote arcing at the points giving you that color.

If you have the one of the two later stock distributors they have an internal capacitor for a radio noise filter and a condenser to suppress flashover on your points. If the condenser is bad you'll get the symptoms of excessive arcing across the points. If the noise filter fails open it can remove or restrict current to the coil. If it fails closed then you will have a direct short to ground and no ignition.

Most coils from our period were always 6 volt. 12V & 24V always use a resistor on the power in to the coil. In the case of our water proof distributors the resistor is built into the coil.

Are you looking for an internal wiring diagram for the distributor?

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

foss0194

Member

Joined: Mar 18, 2017

Posts: 30

|

Posted: Wed Feb 14, 2018 2:46 pm Post subject: Posted: Wed Feb 14, 2018 2:46 pm Post subject: |

|

|

I am not sure about proper venting. Is that checked by just making sure tubes aren't kinked or obstructed or is there air actively pumped into distributor by double action fuel pump?

Not sure about radio noise filter or even if I have one. I haven't seen one in the diagrams or photos that are posted, but I remember them being discussed in other posts about problems.

The resistor in the coil makes sense and we just replaced coil, so that may have fixed the problem... haven't had a chance to drive it much since repair.

Yes, was looking for internal wiring diagram for distributor . |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16365

Location: Wisconsin

|

Posted: Wed Feb 14, 2018 11:59 pm Post subject: Posted: Wed Feb 14, 2018 11:59 pm Post subject: |

|

|

I have not seen an internal wiring diagram for this distributor. Not much need for one. They are very simple. Look closely at my photos above you can see there are only 3 wires.

1 - The wire at the + terminal ( A ) of the coil is about 5" long and goes to the Radio Noise Filter Capacitor in it's housing center front of the distributor.

2 - The wire at the - terminal ( B ) of the coil is about 3" long and goes to the contact point's terminal.

3 - The 3rd wire runs from the contact point's terminal to the condenser and is permanently affixed to the condenser.

The coil is sealed.

The distributor housing is suction vented. Air will flow from the air cleaner thru the crossover tube then thru a small line to the distributor body. Then flows thru the body of the distributor and out thru a small line on the other side of the distributor body around the back of the engine to the wiper "T" and then to the suction side of the vacuum pump and finally up the vacuum pump tube to the intake manifold.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

foss0194

Member

Joined: Mar 18, 2017

Posts: 30

|

Posted: Sat Feb 17, 2018 8:25 pm Post subject: Posted: Sat Feb 17, 2018 8:25 pm Post subject: |

|

|

The resistor question was the main reason i thought i needed a schematic, but since it is in the sealed coil all we can do is replace it if bad.

My vacuum system is not completed... meaning whoever was finishing the restoration before i got it did not complete all the connections. I know for certain the wipers are not connected and the air lines from the dual action fuel pump are in a loop. Could be an airflow problem, however it seems unusual it could be the problem now when it hasn't been in the past...... I have made several different changes to electrical system to include new batteries, distributor instead of generator, new ignition switch, and changes in the wiring harness.... can it perform without a completed vacuum system? can only certain connections suffice since i am not going through water?

What does the resistor drop the 24V to on the other side of coil going to the points? |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16365

Location: Wisconsin

|

Posted: Sat Feb 17, 2018 11:01 pm Post subject: Posted: Sat Feb 17, 2018 11:01 pm Post subject: |

|

|

Leaving the ignition switch on for long periods for testing voltages is not a good idea. There is no need to.

The correct method is to use a coil tester which will measure the voltage drop across the coil accurately. The 2nd best way is to take accurate resistance readings across the coil's primary and then the coil's secondary system, with the coil cool and heated.

The purpose of the distributor venting system is to provide a flushing air flow across the distributor's interior to vent ionized gases. This is accomplished by Vacuum (Suction) not pressure. The dual fuel/vacuum pump's vacuum pump is parallel to the intake so it can boost vacuum throughout the system. There is plenty of info in your M38A1 Engine/Clutch manual TM 9-8015-1.

What did you mean here: | Quote: | | distributor instead of generator, |

? I am guessing you meant to sa alternator in place of generator?

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

foss0194

Member

Joined: Mar 18, 2017

Posts: 30

|

Posted: Sun Feb 18, 2018 11:43 am Post subject: Posted: Sun Feb 18, 2018 11:43 am Post subject: |

|

|

Yep, ment to say alternator... whoops!

Appreciate the info and reference material.

Don't have a coil tester. What is the voltage drop across the coil? Reduces 24v to what?

So it sounds like I need to connect the ENTIRE vacuum system together for the distributor to be vented properly? In your opinion can some not be connected and still work? Got to admit, trying to figure out where all the lines go is intimidating to me, plus missing some parts. |

|

| Back to top |

|

|

4x4M38

Member

Joined: May 30, 2014

Posts: 3459

Location: Texas Hill Country

|

Posted: Sun Feb 18, 2018 12:05 pm Post subject: Posted: Sun Feb 18, 2018 12:05 pm Post subject: |

|

|

You can leave some of it disconnected like the wipers but you must

make sure the rest of the system is air tight. Or vacuum tight, as it were.

Others will offer better info but I would guess the vacuum system needs

to be connected to the fuel pump, carburetor, distributor and crossover

pipe. If you don't have the fuel tank vented as per factory then you need

it vented at the tank like the later M38A1's were.

There are a lot of parts in the system. If you leave some unhooked

you need to be sure what is there is functioning correctly.

_________________

Brian

1950 M38

MC11481

http://www.willysmjeeps.com/v2/modules.php?set_albumName=album372&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16365

Location: Wisconsin

|

Posted: Sun Feb 18, 2018 9:14 pm Post subject: Posted: Sun Feb 18, 2018 9:14 pm Post subject: |

|

|

The main points are:

1 - Do not leave a vacuum line open to just suck air.

2 - Do not restrict air flow in the vacuum side of the fuel pump.

Routing is terribly simple.

Line routing is:

1 - intake manifold to vacuum pump.

2 - vacuum pump to wiper "T".

3 - wiper "T" unrestricted port to wiper shutoff valve.

4 - wiper "T" restricted port to left side of distributor housing.

5 - Right side of distributor housing to crossover inlet duct.

If you do not have a wiper shutoff valve then simply cap that tube.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

foss0194

Member

Joined: Mar 18, 2017

Posts: 30

|

Posted: Tue Feb 20, 2018 2:04 pm Post subject: Posted: Tue Feb 20, 2018 2:04 pm Post subject: |

|

|

Ok, will look more closely at the vacuum system and ensure proper connections and capping.

What does the resistor drop the 24V to on the other side of coil going to the points?

Don't have a coil tester. What is the voltage drop across the coil? Reduces 24v to what? |

|

| Back to top |

|

|

w30bob

Member

Joined: Mar 22, 2017

Posts: 301

Location: Great Mills, MD

|

Posted: Tue Feb 20, 2018 7:05 pm Post subject: Posted: Tue Feb 20, 2018 7:05 pm Post subject: |

|

|

Foss,

The ORD has good diagrams on the fording system, labeled as "Ventiliation System". Wes has put those in his photo album entitled "M38A1 and M170 Fuel System". You can also Google "M38a1 fording" and you'll see tons of pics. There was a guy either on here or over on G503.com (I forget which) who made and sold all the vent lines in a kit......I got mine from AJP and I'd guess all the vendors have it as well.......or you can make them all yourself with some tubing, fittings and a flare tool.

regards,

bob |

|

| Back to top |

|

|

foss0194

Member

Joined: Mar 18, 2017

Posts: 30

|

Posted: Fri Feb 23, 2018 3:01 pm Post subject: Posted: Fri Feb 23, 2018 3:01 pm Post subject: |

|

|

Thanks for the responses on vacuum system.

Do ya'll happen to know what the resistor drops the 24V to on the other side of coil going to the points?

Don't have a coil tester. What is the voltage drop across the coil? Reduces 24v to what? |

|

| Back to top |

|

|

|