| View previous topic :: View next topic |

| Author |

Message |

Ryan_M

Member

Joined: Sep 30, 2013

Posts: 70

Location: Glenburn, ME

|

Posted: Sun Dec 08, 2013 5:27 pm Post subject: Bell crank woes Posted: Sun Dec 08, 2013 5:27 pm Post subject: Bell crank woes |

|

|

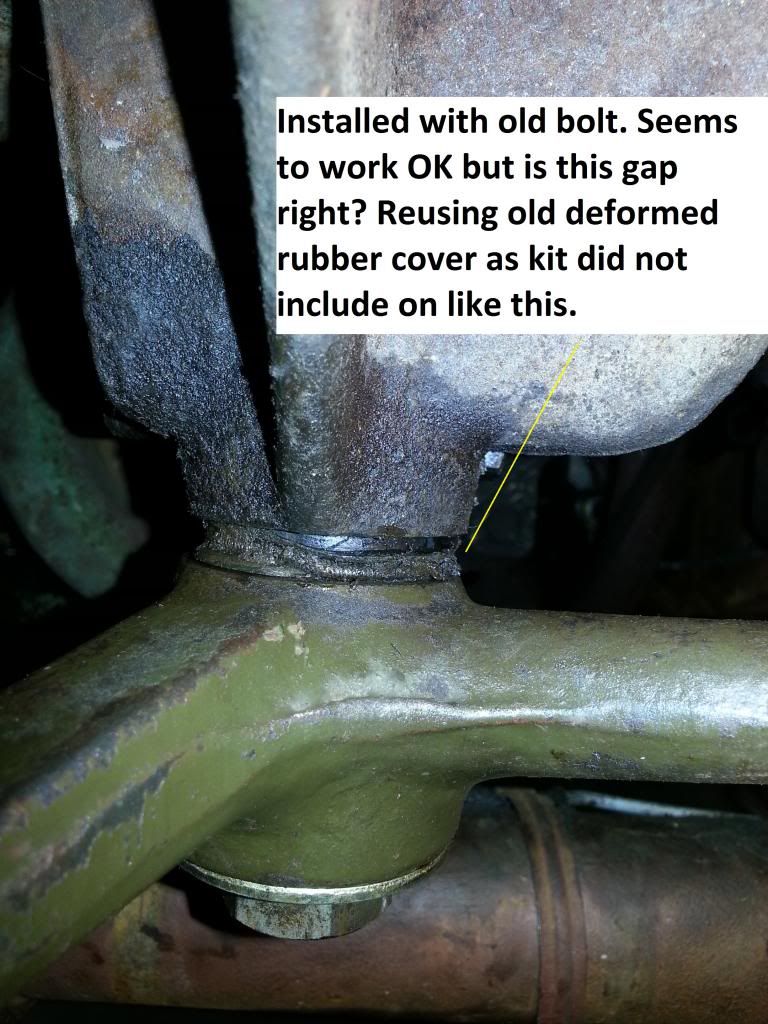

I installed a bellcrank repair kit and am having a tough time getting the bellcrank back on my M38. The inner bearing sleeve hits a same diameter piece coming out of the bottom of the frame mount. When I fully install and torque the nut on the shaft the bellcrank binds and is impossible to move. If I were to drive the bellcrank inner bearing sleeve down it would no longer be flush at the bottom and cause a problem there too. I am cross-eyed from scouring the web for a detailed bell crank install procedure and exact fitment of components. Can someone point me in the right direction or tell what's wrong from the pics? The rubber dust cap has intentionally been left off here.

|

|

| Back to top |

|

|

evanso1975

Member

Joined: May 10, 2010

Posts: 615

Location: North Yorkshire, UK

|

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16249

Location: Wisconsin

|

|

| Back to top |

|

|

Bretto

Member

Joined: Nov 24, 2010

Posts: 1390

Location: Orem, UT

|

Posted: Mon Dec 09, 2013 6:25 am Post subject: Posted: Mon Dec 09, 2013 6:25 am Post subject: |

|

|

Is the bushing maybe too long? How does it compare to the old one?

_________________

Brett

'51 M38

PHOTO DIARY OF MY BUILD |

|

| Back to top |

|

|

Ryan_M

Member

Joined: Sep 30, 2013

Posts: 70

Location: Glenburn, ME

|

Posted: Mon Dec 09, 2013 7:01 am Post subject: Posted: Mon Dec 09, 2013 7:01 am Post subject: |

|

|

I'm really trying to determine if the frame mounted bracket on the M38 is identical to the CJ version. The bracket appears to be sleeved on both models.

On my M38, I replaced the sleeve and bearings in the actual bellcrank but didn't change anything with the bracket. The bellcrank sleeve in the rebuild kit is the exact same as the old one, as are the bearings. The long bolt was different so I went back to using the old one. When I use the old bolt I can really torque down and the bell crank does not bind but it doesn't seem right that the bearing sleeve and bracket sleeve mate face-to-face, leaving a gap. On the CJ, the bracket and bellcrank mount flush together.

I hope these pics make my question easier to understand. You can see the "sleeve" (is it even a sleeve??) in the bracket sticks out a little bit. Is that correct or the work of a previous "Bubba"?

|

|

| Back to top |

|

|

oilleaker1

Member

Joined: May 14, 2009

Posts: 971

Location: South Dakota

|

Posted: Mon Dec 09, 2013 7:31 am Post subject: Posted: Mon Dec 09, 2013 7:31 am Post subject: |

|

|

| Did you compare the inner vertical bellcrank bolt with the old one that works? The cutout for the pinch bolt in the same position on the vertical bolt? I don't recall a sleeve in my frame part. Possible previous owner repair? Once in a tightened , the new vertical sector bolt is fixed and machined to allow the bellcrank to rotate freely. I've not seen where you can get a new seal that does not come in the kit. I reused mine also. John |

|

| Back to top |

|

|

Ryan_M

Member

Joined: Sep 30, 2013

Posts: 70

Location: Glenburn, ME

|

Posted: Mon Dec 09, 2013 7:38 am Post subject: Posted: Mon Dec 09, 2013 7:38 am Post subject: |

|

|

If it is an extra sleeve the diameter is right because the sector bolt slides right through as it should. If I remove it I would be left with too wide of a hole in the mounting bracket. And I'm not sure it would come out anyways.

It's tough to see in this pic but the whole thing is slit from the top to roughly halfway down. This is presumably to it will flex when the pinch bolt is tightened. I can run a razor blade right down that slit from the outside.

The cut-out in the sector bolt seems pretty irrelevant since the pinch bolt doesn't really even slide through it. I think the CJ3A's are the same way? One 2A's I think the whole design is different and the pinch bolt does actually slide through the sector bolt cutout?

|

|

| Back to top |

|

|

ecurb_1160

Member

Joined: Dec 15, 2012

Posts: 37

Location: franklin,pa.16323

|

Posted: Mon Dec 09, 2013 8:00 am Post subject: Posted: Mon Dec 09, 2013 8:00 am Post subject: |

|

|

This is how mine was, I replaced bushings and new bolt. But I don't see the shim washers on top of your bell crank is this what your missing?

[url] [/url] [/url]

This is on a M38A1 but I think they are the same, Bruce |

|

| Back to top |

|

|

Ryan_M

Member

Joined: Sep 30, 2013

Posts: 70

Location: Glenburn, ME

|

Posted: Mon Dec 09, 2013 8:02 am Post subject: Posted: Mon Dec 09, 2013 8:02 am Post subject: |

|

|

| Wow, that's encouraging. A few simple washers may be the answer! |

|

| Back to top |

|

|

ecurb_1160

Member

Joined: Dec 15, 2012

Posts: 37

Location: franklin,pa.16323

|

Posted: Mon Dec 09, 2013 8:09 am Post subject: Posted: Mon Dec 09, 2013 8:09 am Post subject: |

|

|

| RYAN , They allow the bolt to shoulder out, but still leaves the bell crank able to move, hole in them is the size of the bushing that sticks down out of the frame mount. not sure what thickness is on them but they appeared to be ground flat, not just common washers. hope this helps!!!! Bruce |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16249

Location: Wisconsin

|

Posted: Mon Dec 09, 2013 10:27 am Post subject: Posted: Mon Dec 09, 2013 10:27 am Post subject: |

|

|

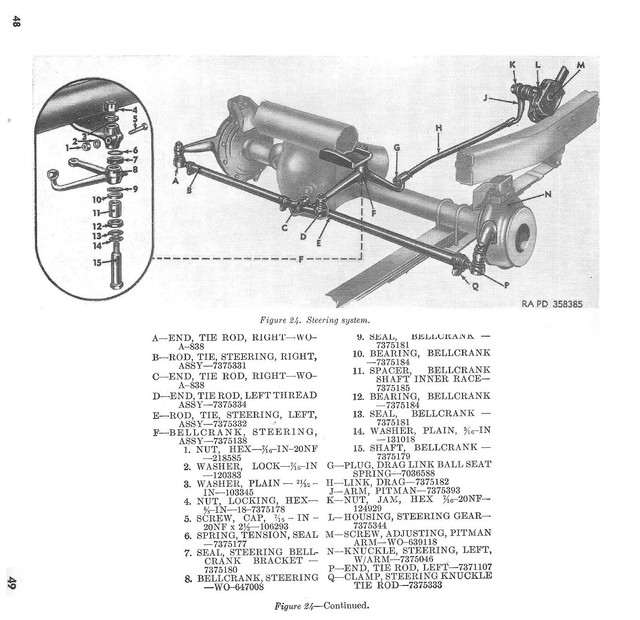

Here's the illustration from the M38 TM 9-1804B

9 & 13 are seals and 7 is a seal but is more a boot. 6 is a wavy spring washer. There are no spacer washers.

There is no need to use any shims there. You are suppose to have two seals. One for that upper gap and one for the lower just above the washer under the bolt/shaft head. Then a boot (also labeled seal) to cover the top seal and the space in your photo.

Keep in mind there are several different diameter shaft bolts.

Note that the CJ2A/3A illustration is virtually identical to the M38 illustration except for the boot (seal) and the wavy spring washer.

Where did you get your kit? What was the kit part number? Did the kit include a list of individual parts' numbers?

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

Ryan_M

Member

Joined: Sep 30, 2013

Posts: 70

Location: Glenburn, ME

|

Posted: Mon Dec 09, 2013 10:36 am Post subject: Posted: Mon Dec 09, 2013 10:36 am Post subject: |

|

|

| So from the looks of the M38 diagram, there is no "sleeve" sticking out of the bottom of the frame mounted bracket. Odd that mine and Bruce's both seem to have that. Between my new kit and existing parts, I have everything in the diagram except for the wavy spring washer (#6 SPRING, TENSION, SEAL), although I question how well it would fit given that exposed piece of frame sleeve. |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16249

Location: Wisconsin

|

Posted: Mon Dec 09, 2013 11:03 am Post subject: Posted: Mon Dec 09, 2013 11:03 am Post subject: |

|

|

I disagree there. That is why the M38 shows the third seal (boot) and the spring washer. It was booted for fording purposes. You must have that space or there's no room for the spring washer and boot. Neither illustration gives a clean shot of the bottom of the bellcrank bracket but I do not recall a factory sleeve inside the frame bracket. It is a common field repair when the bracket's inner bore gets severely worn from neglect. It is the pinch bolt's job to control that vertical space & stop the shaft from rotating. I am guessing your bellcrank bracket was in bad shape and someone reamed it round and fabricated a bushing repair sleeve. If this is the case then the pinch bolt cannot do it's job unless the sleeve is slotted so it can be compressed by the pinch bolt.

_________________

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules.php?set_albumName=Wes-Knettle&op=modload&name=gallery&file=index&include=view_album.php |

|

| Back to top |

|

|

Ryan_M

Member

Joined: Sep 30, 2013

Posts: 70

Location: Glenburn, ME

|

Posted: Mon Dec 09, 2013 11:11 am Post subject: Posted: Mon Dec 09, 2013 11:11 am Post subject: |

|

|

Very sound explanation - especially "You must have that space or there's no room for the spring washer and boot". Makes sense.

I'd still be curious see a clear shot of the bottom of an original bracket. Is it sleeved or is cast with that sleeve-like protrusion?

Either way, thanks for all the input. I'll add a spring washer to mine. |

|

| Back to top |

|

|

wesk

Site Administrator

Joined: Apr 04, 2005

Posts: 16249

Location: Wisconsin

|

|

| Back to top |

|

|

|