Page 2 of 3

Posted: Tue Nov 14, 2023 9:07 pm

by wesk

Half copper and half phenolic equals half insulation protection. It is that simple. There are sheets of bare phenolic out there. Look for them.

Posted: Wed Nov 15, 2023 7:30 am

by RonD2

Just a thought JeepDaddy,

If you could get a measurement (or s.w.a.g.) of the slot where it fits, you might find that a piece 1/16th-inch think (.062") could work just as well as the stock 3/64 (.047) piece.

Hard to imagine that the .015" difference (x2) would cause problems in a mechanical switch like that.

And from google, it looks like 1/16-inch sheet is a lot more common than 3/64.

You might also search using the trade names "Micarta" and "Garolite" as it's commonly known to get more hits like these:

https://www.mcmaster.com/85315K111/

https://www.amazon.com/Sealing-G-10-FR- ... 49T68?th=1

Hope this helps.

Good luck!

Posted: Wed Nov 15, 2023 9:36 am

by Xamon

If you had the appropriate acid for making the circuit boards you could use it to take off the copper. Haven't done that since high school so I don't remember what it is called, or I guess you could sand it. just some thoughts.

Posted: Wed Nov 15, 2023 9:49 am

by RonD2

You might also consider using a modern plastic like ABS or Delrin that have good temp and electrical insulating characteristics:

https://www.ebay.com/itm/363344971248?h ... R_Km0br6Yg

Posted: Wed Nov 15, 2023 12:19 pm

by JeepdaddyRC

Thank you for the feedback Rond2 and Xamon.

I ordered an "electrical-insulating Garolite sheet" in 1/16 thickness from McMaster-Carr (part #8525K111).

I'll let you know if it fits. The original was .05 (3/64) but I was unable to locate that thickness (without the copper side.) I'm concerned if it is too snug inside the starter switch, the plunger could bind up. The plunger needs free movement to back off the contacts when the switch is released. Since I don't currently have a master battery cutoff switch, that could be a problem.

Posted: Thu Nov 16, 2023 4:10 pm

by JeepdaddyRC

No joy. Too big. Not enough room inside switch. Purchased NOS switch. I stlll have 18 volts at terminal A while cranking.

I’m sure there is some voltage drop while starter is cranking. What should voltage be at terminal A with ignition off while cranking?

Posted: Thu Nov 16, 2023 10:15 pm

by RICKG

i had a switch blow out in 2017. Search phenolic and find my post "24V starter switch failure " sept of 2017. i sourced .030 phenolic and made up a handful of doghouses and they work well. i think i have a few left if your other options fail.

Posted: Fri Nov 17, 2023 8:31 am

by JeepdaddyRC

My NOS starter switch also shows 18 volts when cranking and starter cranks slowly.

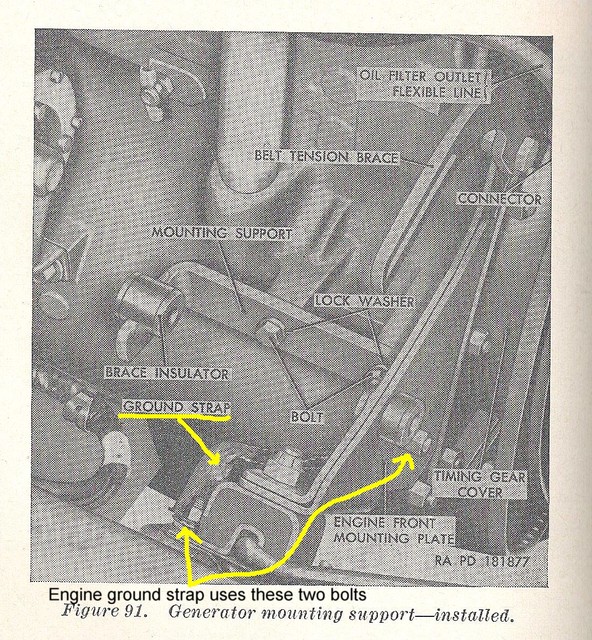

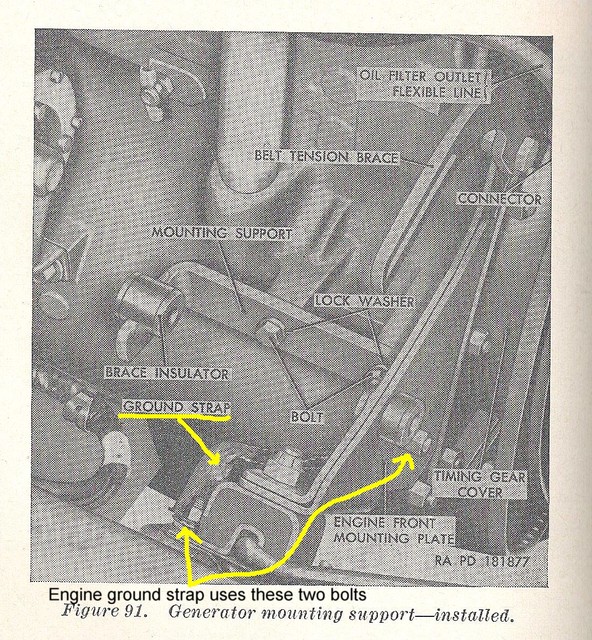

I found the front support bracket on the starter motor is missing. In addition, the ground strap at engine mount is under the large nut on top of the engine mount, not the side bolt as pictured below.

1. Could this be a bad ground issue?

2. Would it be helpful to run a dedicated ground from frame to starter bolt?

3. Should a dedicated ground to the starter be a 2-gauge cable similar to the battery ground cable, or is that overkill?

Posted: Fri Nov 17, 2023 10:49 am

by wesk

A quick and simple answer to your questions is a heavy gauge jumper cable clipped on the starter mount bolt and the frame ground point and run your crank test again.

Posted: Fri Nov 17, 2023 8:16 pm

by JeepdaddyRC

Thinking this could be a ground issue, cleaned connections and battery terminals. Jumper cable from ground to starter suggested above by Wes.

Battery voltage prior to cranking = 26.5 volts.

Depressed starter switch (with ignition off). Voltage = 24.9 and slowly dropped while cranking. Better than the 18 volts seen previously, but not sure if the initial 1.6 voltage drop and continued slow drop meets specs.

See photo below of the incorrect chassis ground to engine block.

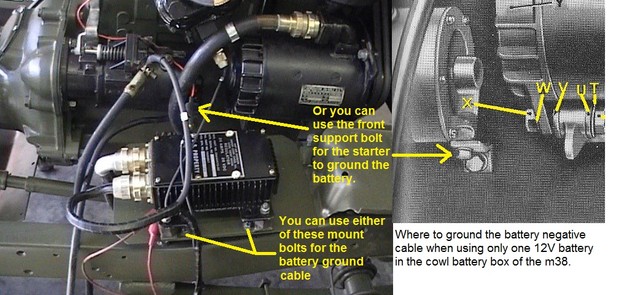

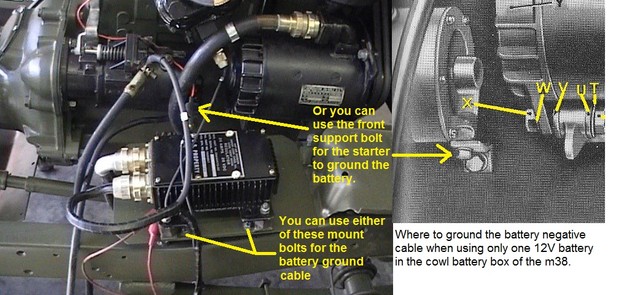

Per the photo above, the ground strap should go from engine mount SIDE bolt to engine front mounting plate. Where is this strap then bolted to the generator?

MWM photo below of M38 ground strap from side bolt to engine front mounting plate and continuing on to a generator bolt per John B.

Posted: Fri Nov 17, 2023 8:56 pm

by RonD2

Hi Jeepdaddy,

A little off topic, but your motor mount looks odd to me.

There's supposed to be metal encasing the rubber on the top as well as the two sides where it bolts to the frame.

And the tunnel where the radiator support rod fits is also supposed to be metal lined.

Maybe it's just hard to see in your photo.

Here's a photo of the M38 motor mount:

https://shop.midwestmilitary.com/produc ... mount-m38/

Posted: Fri Nov 17, 2023 10:00 pm

by wesk

JeepdaddyRC,

Ron is correct your mount rubber is not the correct mount rubber for the M38 side mounts.

Back to post topic: Where on generator do you connect ground strap? Answer is on the M38 you do not. The M38 ground strap only has two holes. One for the aft base bolt on the right engine mount and one for the bolt in the front mount plate.

The strap in John's photo and it's ORD# 7374965 is for the M37's voltage regulator. It attaches to top and bottom of each of the regulators 4 mounting studs. It will fill the bill for almost any ground strap that is the same length or shorter and the same width.

The correct ground strap for your M38 is either the early WO# A1098, ORD# 7371311, FSN 6140-361-7444 (7 1/2" long, 15/16" wide) or the late superseding strap ORD# 811650 (These are AWG No. 4 and are 25/32" wide and about 7" long).

Posted: Fri Nov 17, 2023 10:32 pm

by JeepdaddyRC

Thank you. I see the difference in the engine mounts.

Will continue to improve grounds by adding missing starter front bracket and correct chassis ground strap.

Does that voltage drop during cranking seem reasonable?

Posted: Sat Nov 18, 2023 12:32 am

by wesk

If you read the manuals carefully they only score the battery's cranking ability using amperage. There is no published standard voltage drop for your jeep. Actual voltage drop has way too many variables from battery temp to engine compression to battery state of charge and on and on.

Posted: Sat Nov 18, 2023 8:45 am

by JeepdaddyRC

It is an RMC engine. Perhaps that explains the non original motor mounts?