Page 12 of 13

Posted: Fri Dec 23, 2016 7:02 pm

by wadefreedomvehicles

Past couple days Iv'e bee working hard. I have fuel lines hooked up, all breather lines hooked up. Now I am working on hooking up minimal electrical to get her started and running. Also trying to hook up speedo cable.

I made a bet with my uncle I couldn't drive it on Sunday. So there is now money riding on my having it driving by then

Posted: Sat Dec 24, 2016 9:58 pm

by wadefreedomvehicles

Christmas eve spent well.

Worked all day to get basic electrical hooked up to start it.

I turned the engine and it started to go and then I heard a slight pop/crack. Thought nothing of it.

Then I was getting to electrical to plugs. So I check my distributor. Wasn't turning.

Looked up why it wasn't and found a thread on here about it.

Well, pulled the oil pump and the gear on the oil pump is destroyed. I thought maybe my camshaft would be saved. It had on tooth or groove halfway chipped off.

Is it bad to run it that way, probably.

So now I need to replace the camshaft. Is there a way to do that easily and fast?

What is the best thing to do in this situation?

I will get some pics up later.

Thanks!

Posted: Sat Dec 24, 2016 11:47 pm

by 4x4M38

Ahhhh, Man.

Hoping better for you Wade.

Keep your head up.

Posted: Sun Dec 25, 2016 1:43 pm

by wesk

Is it bad to run it that way, probably.

So now I need to replace the camshaft. Is there a way to do that easily and fast?

What is the best thing to do in this situation?

1- Yes

2- Not very easily. It can be done with the engine in the jeep but you still need to remove the radiator, remove all the lifters, tie up all 8 cam followers, and pull the cam & gear assembly out.

3-You haven't mentioned the obvious question.

What Caused This? A piece of something (metal) jammed those gears and caused the oil pump driven gear to shatter. The only way to be sure all the pieces of metal are out of that engine now before you install a new cam is to disassemble and flush the block. It sucks but it is the only safe course of action if you prefer not to go thru this same exercise in the near future.

Posted: Sun Dec 25, 2016 9:29 pm

by wadefreedomvehicles

Ok Thanks.

I want to try to avoid removing the head and stuff. I want to remove as little as possible.

But for now I am in search of some valve spring compressor wrench things and a new cam.

I will probably have to remove the oil pan and look for those chunks of metal.

Posted: Sun Dec 25, 2016 11:45 pm

by wesk

The less you disassemble the higher the risk for the same problem again in the near future or worse yet a plugging up of the oil pickup screen and destruction of bearings with the loss of oil pressure.

When (date) was the last engine rebuild and the mileage since that rebuild?

Posted: Mon Dec 26, 2016 12:45 pm

by wadefreedomvehicles

Well, I bought this engine from a guy who had it in his Willys Slat grill. He said he pulled it and it sat covered and protected in a shed since 2009ish.

When I got the engine I sent it to my buddy who went and replaced gaskets and rebuilt fuel pump and carb and got it all ready to set in. When he pulled it apart, he said that it looked like it had been recently rebuilt and so I had nothing to worry about.

But alas, now this cam is broken... The cam seemed strong, I think it was that the oil pump was weak and the gears broke and it snapped one of the teeth on the cam gear.

Oh man, this is just really crappy.

Posted: Mon Dec 26, 2016 2:09 pm

by RICKG

wadefreedomvehicles wrote:

Oh man, this is just really crappy.

For lack of a stronger word.

I'm feelin it Wade.

Posted: Mon Dec 26, 2016 5:16 pm

by wadefreedomvehicles

Thanks Rick.

Posted: Mon Feb 20, 2017 4:00 pm

by wadefreedomvehicles

Out working on my Jeep again.

Pulled everything off necessary to remove cam shaft. I just need to pull the timing gear and lift the valves up and then pull the shaft.

And then put it all back together and hopefully it will work.

Posted: Mon Feb 20, 2017 6:15 pm

by wesk

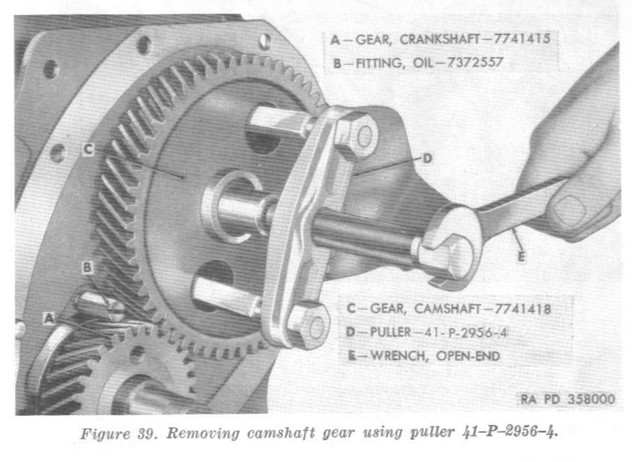

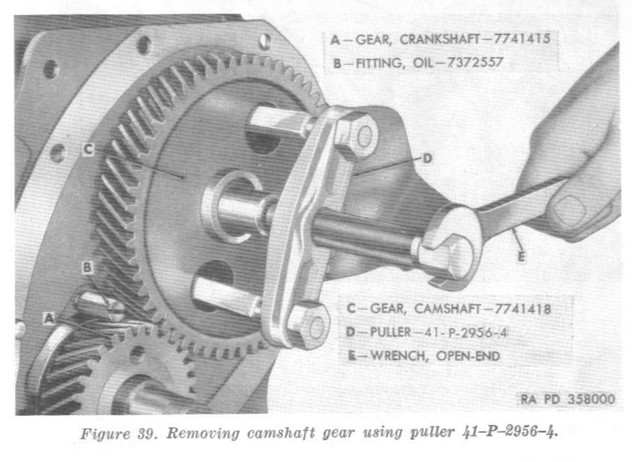

Careful with that phenolic gear. They break very easily, especially if you use the wrong type puller.

Before you pull the gear check for timing marks. Many replacement gears did not have them. If no marks put #1 TDC and align the crank gear timing mark with the cam gear midway between the contact surfaces of the gear teeth on either side of the contact area. Make a match mark on your cam gear.

Posted: Tue Feb 21, 2017 12:04 pm

by RICKG

wadefreedomvehicles wrote:Out working on my Jeep again.

Pulled everything off necessary to remove cam shaft. I just need to pull the timing gear and lift the valves up and then pull the shaft.

And then put it all back together and hopefully it will work.

hopefully

isn't good enough Wade.. are you certain you have identified and repaired the root cause of the destruction? You say the oil pump gear was destroyed-was the pump turning freely with correct clearances? What all did you find in the pan and are you sure you have cleared all debris? You've done a lot of good work on this project, let's not destroy an L134.

Not trying to be hardnosed my friend, just want to see you succeed.

Posted: Tue Feb 21, 2017 4:58 pm

by wadefreedomvehicles

The Oil Pump was completely seized. When it was rebuilt, the guy who rebuilt it used liquid gasket maker...

I still need to drop the pan and find debris.

Wes, I will make sure to set the timing properly if the marks are not already there.

Thanks for all the tips and tricks.

I think for ease and for sake of doing it right, I will just pull the head....

I really don't want to, but would rather do it right the now second time, then have to go back into it a third time.

Thank you all.

Posted: Tue Feb 21, 2017 7:37 pm

by wadefreedomvehicles

Also Another question.

How do I pull the cam? does it come out with the gear? what is the best way to get the cam out?

Thank you.

Posted: Sat Mar 25, 2017 10:25 pm

by wadefreedomvehicles

Got the head off today and all the valves out, now I just need to do the timing marks and such and then pull the cam, I tried to pull the cam, but it is really stuck, so any tips on how to pull the cam after I have the valves and such out?