Page 1 of 1

Taillight hole cutout

Posted: Wed Dec 23, 2020 5:11 pm

by CoastieReid

On the M38;

What diameter is the hole cutout for the taillight?

I have to drill them in mine. Bracket is in place behind, the pilot hole is ready. Now just need to know the diameter so I can get the right hole saw.

Posted: Wed Dec 23, 2020 6:22 pm

by RonD2

Hi Coastie,

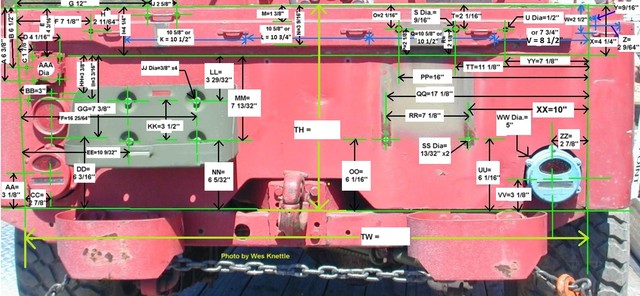

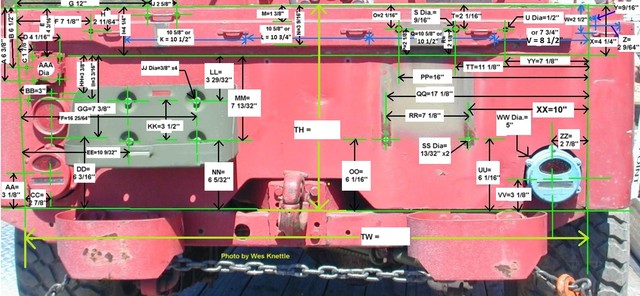

Mine measure 5-inches. I couldn't find a photo for the M38 in Wes's album, but he has a folder in his album on page 1 titled for the M38A1-M170 rear body that also shows the taillight cutout measurement being 5-inches diameter. All these jeeps use the same taillights so it makes sense the holes are the same size. Maybe someone else can take a measurement and confirm it for you. Measure twice, cut once.

You need measurements to properly locate the center of the holes? Nevermind, I see you already have pilot holes ready.

Here's the photo from Wes's album if it helps ("WW" on the right side):

Posted: Wed Dec 23, 2020 11:34 pm

by RonD2

By the way, after looking at the (yikes) price of 5-inch metal hole saws (out of curiosity), I thought that replacement panels I've seen already have the holes cut in them? Cheaper in the long run? Did you fabricate new panels?

Maybe it's just me, but I really cringe when I have to buy a tool that I know I'll only use once or twice in a lifetime.

Especially when I can't find it when I need it....

Posted: Thu Dec 24, 2020 4:27 am

by CoastieReid

I have a bunch of hole saws already from other projects over the years.

The plain panels were cheaper than the precut ones by far. By me cutting the hole would save me money. I think I bought one passenger panel on here from someone a year ago. At a discounted rate compared to new.

This Jeep is a money pit for sure. I know this.

I always can use more tools..... I probably already have the right size hole saw anyway. I have a whole drawer full of them in one of my tool boxes.

Posted: Tue Dec 29, 2020 3:27 pm

by dpcd67

I cut them without a hole saw; those cost $.

scribe the circle, and drill 1/4 inch holes all around inside the like. Snip the metal out with wire cutters. Smooth up the ID of the hole with a sanding drum, and I also used a carbide burr.