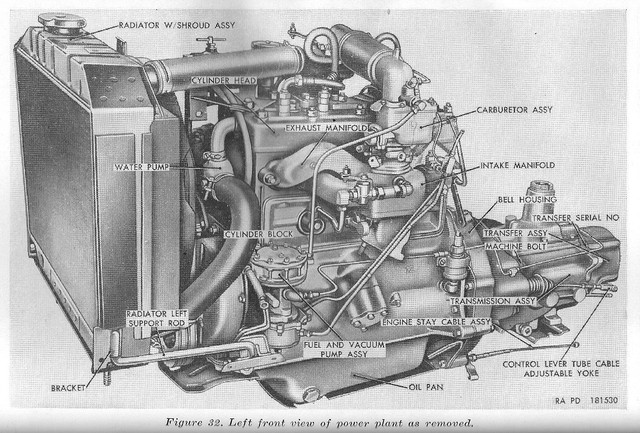

(Nice pics. Thanks. I do study the albums, without which this M38 Spruce Goose would have never got off the ground.)

———————————————————————-

Yep. Looks like those puppies got snatched and pulled beyond their intended specs.

I heated (hand torch probably not hot enough) & pounded both sides which extended the space between the rings but the crossover tube fit was still a little tite and a small crack opened up at the base of one ring.

These simple things often take me more time/effort than expected. It’s like, “Well that looks easy”, and an hour later you are still at it. Same with looking up general shop procedures ...... there are always several opinions on most everything. These things happen when a person with little auto background attempts to resurrect a M38 barn find but with patience and perseverance I am usually able to overcome my ignorance and lack of skill.

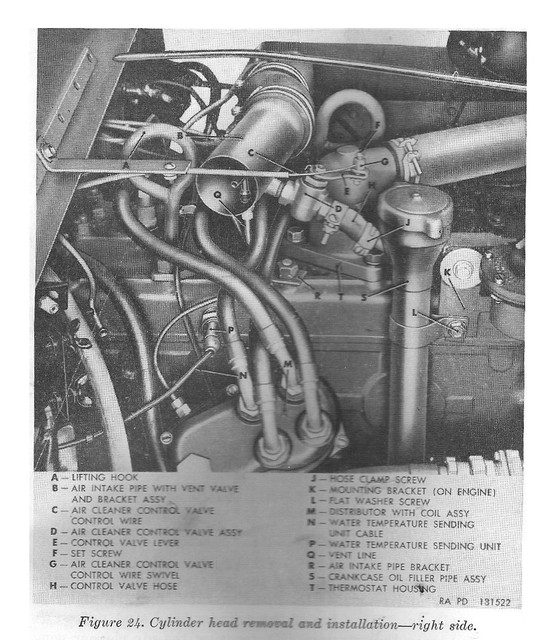

Any-who, I am going to cut the lifting hook base on one or both sides by 1/2 the diameter, heat ‘em up, bend ‘em straight and weld the cuts solid.

If that doesn’t work I will cut the lifting plate into 37 pieces, melt the steel in a Bessemer Converter or volcano, extrude the parts for the base & rings, reconstruct the entire assembly and bolt it through the head, block and frame.