Page 1 of 1

M38a1 clutch problem

Posted: Mon Oct 31, 2022 10:25 pm

by RichJohnson

So this is going to sound strange but bear with me ok.

Last year we rebuilt the motor in my M38a1 and I put a new clutch and pressure plate from Walks 4wd in the vehicle.

When it was all back together the clutch would not release when the pedal was stepped on. Yes we had the proper freeplay and throw.

So we took the floor back out and removed the inspection cover and with the engine off, pushed the clutch pedal and pushed on the clutch with a bar to spin the clutch inside the pressure plate.

The clutch would spin most of the way around just fine and then catch very tightly requiring alot of pressure to push it past this tight spot.

Eventually we tried putting it in gear in 3d with the wheels chocked and rubbed the clutch gently and the high spot went away and ran fine for one year.

Now, here I am suddenly the clutch is sticking nearly every time I step on it over the last couple days and it has gotten worse. Now I have to jam it hard to get into first gear as the clutch is still spinning with the flywheel. Pedal travel is still appropriate. About an inch of freeplay until pressure and then slight pressure the throwout bearing touches the pressure plate fingers.

Have you guys heard of new pressure plates doing anything like this? Does Walks have bad chinese crap that fails?

Where should I buy a clutch and pressure plate from?

Am I going to have to pull my engine to fix this or get under it and pull the gear box assemblies back to do the job?

I really dont have that many miles on this thing in one year.... Im a bit peeved right now.

Posted: Tue Nov 01, 2022 6:40 am

by BBDE

Hello Richard,

Have you checked the rear clutch lever and see if the levers are in the correct position.

The levers must be aligned opposite each other.

There are repro parts out where the levers are in the wrong position and the pedal travel is not sufficient for the clutch to disengage properly.

It is also important to check the basic setting of the arms on the pressure plate and adjust them if necessary.

When installing the gearbox, the pilot bearing can get a degree and then take the gearbox shaft with it, which can also ensure that the clutch does not disengage properly,which can also happen if viscous grease is made into the pilot bearing.

If there is grease on the gearing of the transmission shaft and the drive plate, there can also be problems with the clutch.

Frank

Posted: Tue Nov 01, 2022 8:15 am

by RichJohnson

I will look for the grease when I open it up to look inside.

As for the levers, they are all what came on this jeep from the army. I bought it at auction a long time ago, Im the first owner outside the military.

It worked the clutch fine for years until suddenly a couple days ago.

Posted: Tue Nov 01, 2022 11:42 am

by wesk

Certainly sounds as if you have a clutch facing issue or a pressure plate issue. I still suggest starting your troubleshooting at step one in TM (-8014 page 92 Par 92 Clutch thru the end of that section. Keep in mind these troubleshooting charts were designed for at least trained motor pool mechanics use and where it mentions sending the jeep & problem to ordnance just assume this is where a more specialized technician is used.

If you find no relief of your problem here in TM 9-8014 then the next step is a thorough inspection of the clutch disc & pressure plate assembly. Only two ways to do this. Crawl underneath and pull the tranny /transfer cases out of your way and start. This is of course the hard way. Option two is to separate the engine block from the bell housing and lift the engine out where it is quite easy to continue you inspection.

Posted: Tue Nov 01, 2022 7:09 pm

by RichJohnson

My friend wanted to come over and see what I was talking about before I did anything.

So tonight he came over and we started driving around the neighborhood, starting and stopping to exercise the clutch. It had no problems at all for quite a bit and he thought I was crazy until it finally started doing it when the jeep fully warmed up.

Once it warmed up, the clutch began catching and continuing to spin while the pedal was depressed every time. One can still pull the shifter hard and jerk it into gear and then the grinding spinning sound gets even louder.

Next I guess I pull the floor out and take the inspection plate off to see what we can find but based on what I experienced when we installed it and had that rubbing issue and saw nothing, I dont expect to see anything.

Any quick ideas what would cause this only while warmed up and not cold?

Posted: Wed Nov 02, 2022 11:27 am

by 4x4M38

By all means follow Wes’ advice with the troubleshooting guides.

Just for grins, you might reach in the inspection hole and wiggle your throw out bearing. It should be a tight assembly. Mine rattled like a can of bolts.

Of course the clutch would not release.

Posted: Wed Nov 02, 2022 7:07 pm

by RichJohnson

Yeah I went right to the manual and I have the proper free play in the pedal before the throwout bearing hits the pressure plate.

I wind up at send or ordnance personnel

Its weird it runs great cold for a while till it warms up then starts sticking.

Just seems bizzarre that it acts this way.

The floor will come out saturday to see what is going on but I dont really know what to look for other than something obvious

Posted: Wed Nov 02, 2022 9:20 pm

by wesk

but I don't really know what to look for other than something obvious

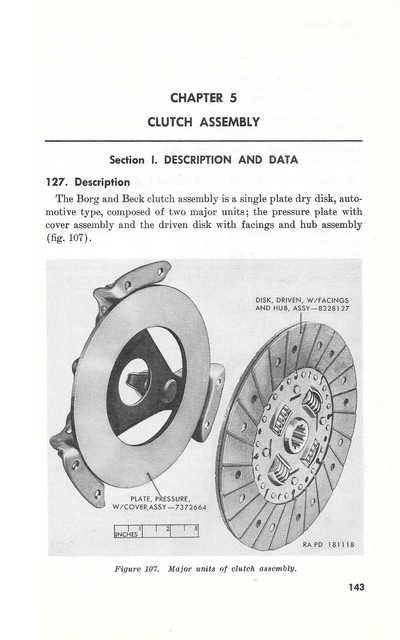

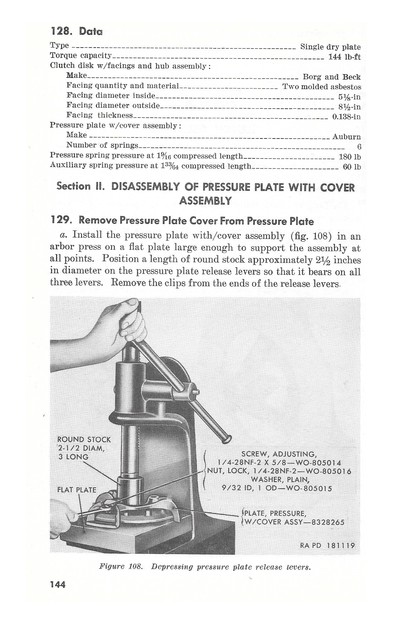

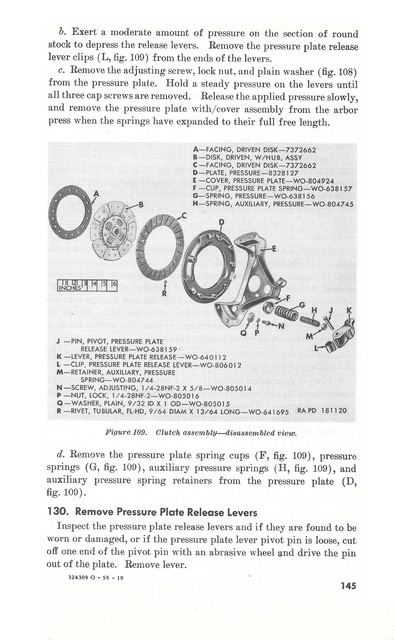

You only mention going to one manual. Had you looked at TM 9-8015-1 "Ordnance Maintenance Engine &

CLUTCH you would have a nice list of things to check during your teardown and inspection. Pages 143 thru 147. In this hobby the "Do-it your selfer" has only one super reliable and usually free source of technical knowledge. The Manuals. You can never have enough of them. There are tons more manuals out there besides the 3 basic M38A1 manuals and parts catalog. Chilton's old reliable repair & tune-up guide "Jeep CJ 1945 to 1984" is a super little manual. Just google them up and download them for free.

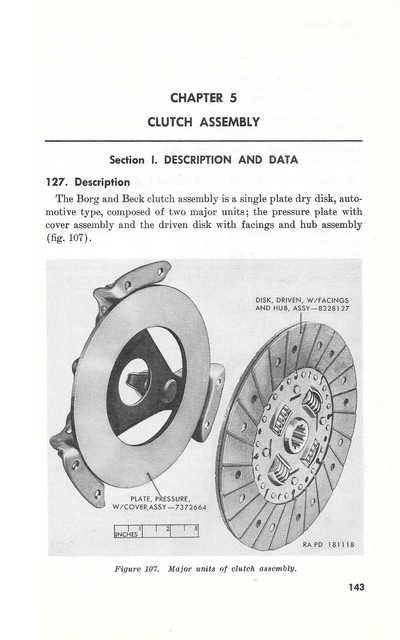

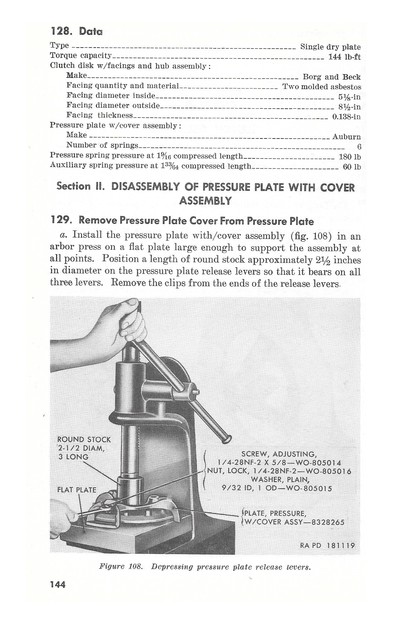

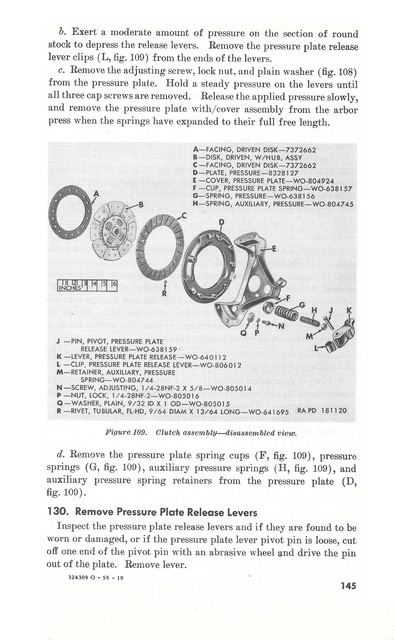

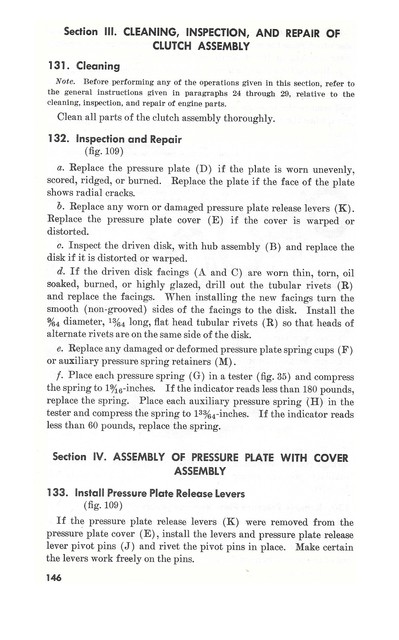

Here's Chapter 5 Clutch in TM 9-8015-1

Here a great manual to study, one that just about every motor pool mechanic has a copy of:

TM 9-8000 Principals of Automotive Vehicles

Here's another great manual:

And another you should put in your library:

And the early CJ5 popular factory manual:

And the 1st factory manual to include the CJ5:

All of these can be found in paperback at reasonable prices used on google and at jeep shows and all can be found in PDF format as free downloads if you look hard enough.

Posted: Thu Nov 03, 2022 4:14 pm

by Pierre

Just got my TM9-8000 1956 version that I found on Ebay for a big $9

Nice to have the real paper version. You just have to be patient...

clutch problem

Posted: Fri Nov 04, 2022 9:32 am

by dally1

I had the same problem found the clutch cross shaft in the wrong way around

Posted: Sat Nov 19, 2022 11:58 am

by RichJohnson

I dont have the Army clutch TM.

I didnt see anything in the bellhousing that was out of ordinary.

At this point I can drive it for a while until the clutch starts to catch so Im just going to keep driving it till something breaks.

My friend suspects the pilot bearing is gripping the trany shaft after it gets hot from friction but its just a guess.

Without any way to pull the motor or trany it doesnt really matter I cant do anything about it but live with it now.

Posted: Sat Nov 19, 2022 4:32 pm

by Mike_B

Have you confirmed the linkage Bell Crank in installed correctly per Dally's post?

Pulling the trans is not that big of a job...floor jack and basic hand tools should do it...

Mike B

Posted: Sat Nov 19, 2022 6:39 pm

by rgmutchler

You might find it better to diagnose and fix rather than let it break and see what else it takes with it. You said you have no way to pull the mtr/tran. If you drive it until it breaks you have to pull it then. I am pretty sure there are some tool and equip rental places that you can rent and engine hoist for a day.

Posted: Mon Nov 21, 2022 7:47 pm

by RichJohnson

Mike_B wrote:Have you confirmed the linkage Bell Crank in installed correctly per Dally's post?

Pulling the trans is not that big of a job...floor jack and basic hand tools should do it...

Mike B

Yes.

At this point I drove it quite a bit yesterday and didnt notice any issue with the clutch. It was happening only after a while of driving. And like I said earlier, it has run fine for a year after the motor rebuild and the trans transfer was not moved at that time so the Z bar has not been removed in 20 plus years if ever I cant remember.

Not seeing any issues just means there is nothing to fix until you can find an issue that needs fixing. If I wait unitl the clutch stays spinning and is then nearly undriveable or totally undriveable and does not just go away when it cool down then I can find it and fix it. Say hypothetically the trans shaft sticking in the pilot bearing, then I will have a problem I can find and fix. Make arrangements to deal with it and replace the pilot bearing, which my friend thinks it might be.

Or locate the problem on the clutch disk or pressure plate. Right now, without it sticking when Im looking and being able to find it, tearing everything apart would likely be a fruitless fishing expedition.

I know this sounds lazy but I troubleshoot equipment for a living and if you cant find an intermittent failure you cant fix it unless you can at least isolate it to a component.

I would hate to just pull everything and replace all of it becasue that is what I would have to do again to be sure I get rid of whatever problem it is.

Like I said guys, I can drive the jeep normally for quite a while running errands and so far I have not made the problem come back since the first couple of times.