Page 1 of 2

Cleaning douglas connectors

Posted: Sun Apr 13, 2014 7:56 am

by Thunderbird712

I am looking to clean up all the Douglas connectors on my wiring harnesses. They are all dirty from use and then the jeep sat outside under a cover for a while before I started the restoration. I was thinking of just wire wheeling them and clear coating them to prevent corrosion. Any other ideas or a better method to make them last? I want it to look correct as well. Thanks

Posted: Sun Apr 13, 2014 8:17 am

by wesk

They had a yellow cadmium coating originally. So wire wheeling would remove that leaving a dull gray look. Might try experimenting with several cleaning chemicals. The usual method is blast and replate.

Google "Cleaning cadmium plated metal" for a lot of interesting reading on the topic.

Posted: Sun Apr 13, 2014 9:49 am

by kenperkins

I have had good luck using a brass tumbler but, they will need re plating.

Posted: Sun Apr 13, 2014 1:02 pm

by Thunderbird712

Thanks. I had tried the wire wheel on one and didn't like the result as it left the dull gray look as you said. I had looked for some type of cleaning agent but some of the shells are beyond that point with corrosion starting. I am looking into buying the Caswell plating kit to do small jobs like this so that is actually an option. My only problem is that I don't have the right crimping tool to redo the terminals so maybe just doing some splicing further down so I can get the shells off. That is the easy part to figure out. I didn't realize they were cadmium plated so that will help with figuring it out.

Posted: Sun Apr 13, 2014 6:13 pm

by wesk

The point of deterioration problems on wiring is the point where the wire enters those shells. The old dried out and cracking wires short against the metal shells and when the shell rubs a metal object that short goes to ground. Do yourself a long term favor and do it right. Just about all the M series truck dealers stock the crimper, the wire, the connectors, the ferrules and the pins. You can also solder the wires into the pins.

Posted: Sun Apr 13, 2014 8:16 pm

by Thunderbird712

Your correct. That is the right way. I was doing some more reading and looking over my harnesses and a lot of the shells maybe cleaned up without having to be removed. Although if I re-plate a couple of them it might look off. Either way the more I thought about it splicing was a quick fix and I am not about that. Your replay just furthered me along the right path. The article written a few years ago by a member about redoing the connectors well help a lot as well as the numerous posts.

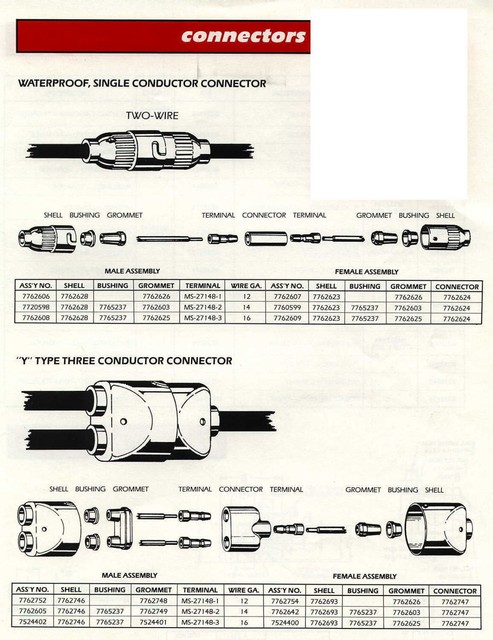

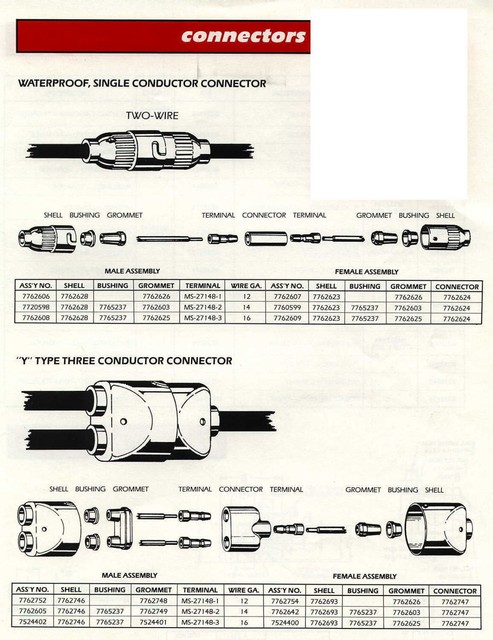

DOUGLAS CONNECTORS - DOING IT RIGHT

Posted: Mon Apr 14, 2014 1:16 am

by bluewatersailor

I recently built a new main harness for my 1953 M38A1. A few of the things that I learned:

1. UCOM INC (

www.ucominc.com) sells all of the douglas components and they don't have a minimum order.

2. By removing the rubber grommet, you can easily slip the shell and bushing over the terminal without having to cut anything. Those grommets are usually rotten and I paid UCOM 60 cents each for replacements.

3. Use a little dielectric grease to ease reassembly.

4. soldering the new or recycled terminals to the wire is easy and probably better than crimping. Set up a jig to hold the terminal in a vertical position while heating, add some solder and then just slip the wire in. For my jig, I drilled a shallow hole in the end of a big bolt and then clamped it in my bench vise.

5. Saturn Surplus sells the aluminum wire marker bands at $9.00 for 144 pieces.

Enjoy! David

Posted: Mon Apr 14, 2014 5:51 am

by Thunderbird712

David,

Thank you for the advice. I am lucky in that the wiring harness is a fairly new one. It was purchased about 10 years ago but between the fun we had trail riding with the jeep and then sitting outside under a cover for a while the shells need to be cleaned. I am doing a full up resto on it so its got to look nice again. Everything else looks in good condition but a good inspection will need to occur. As Wes stated it is probably a good idea I redo the ends anyway and any advice and first hand experience such as yours is welcome.

TJ

Cleaning Douglas Connectors

Posted: Mon Jul 11, 2022 7:40 am

by spinnerhawken

Looking to reignite this thread on cleaning Douglas connectors.

Since this thread was started has anyone landed on any chemical process - commercially purchased and/or homemade solution - to get the old connectors cleaned enough to replate?

Against some of the online advice I have read here and elsewhere I have gone ahead and started (re)building parts of a wiring harness and although I am using new wire, want to reuse the metal Douglas connectors. I do not have access to any blast cabinets/wire wheel/ultrasonic cleaners at the moment and am looking for a chemical-type solution.

To be totally honest, I really kinda like the process of building the harness. A bit therapeutic in many ways, until my wife walks into the apartment...

Posted: Mon Jul 11, 2022 1:12 pm

by jake138

Just a word to the wise for anyone who discovers this thread and is considering mechanical means for removing Cadmium plating (a.k.a. Cad plating):

Cadmium is a toxic heavy metal and is a known carcinogen that "targets the body's cardiovascular, renal, gastrointestinal, neurological, reproductive, and respiratory systems"

https://www.osha.gov/cadmium

A quick search on Google provides at least one forum with some purportedly safe suggestions for chemical stripping of cad plated components:

https://www.finishing.com/313/91.shtml

Re: Cleaning Douglas Connectors

Posted: Mon Jul 11, 2022 2:12 pm

by RonD2

spinnerhawken wrote: - to get the old connectors cleaned enough to replate?

I guess I'm confused.

Won't the plating company clean them anyway before re-plating them as part of the paid-for process?

Side benefit: the plating company handles all the toxic mess.

Or -- are you asking about some kind of home-brew plating kit?

The cost of buying brand new shells with fresh plating isn't all that much if you shop around.

Can your used shells be re-plated cheaper than buying new shells?

Posted: Mon Jul 11, 2022 7:36 pm

by 4x4M38

I thought about lacquer as a coating after wire wheeling.

It yellows with age.

Might take a while…

Re: Cleaning Douglas Connectors

Posted: Tue Jul 12, 2022 10:59 am

by spinnerhawken

Hey Ron,

Great points. I am asking as I am planning on cleaning and reusing what I have. For the most part they are in good/usable condition however, they do need to be cleaned and replated, if anyone knows a way to do it 'home-brew' style. I have done a bit of research on the different home plating methods that could be used but thought I would ask the group in case someone found a method that works for them.

you may be correct if there isn't or if it is too much time or concern, to just replace with new, but like everyone I am trying to learn a bit and keep costs down but not at the sake of my own health.

Posted: Tue Jul 12, 2022 11:01 am

by spinnerhawken

jake138 wrote:Just a word to the wise for anyone who discovers this thread and is considering mechanical means for removing Cadmium plating (a.k.a. Cad plating):

Cadmium is a toxic heavy metal and is a known carcinogen that "targets the body's cardiovascular, renal, gastrointestinal, neurological, reproductive, and respiratory systems"

https://www.osha.gov/cadmium

A quick search on Google provides at least one forum with some purportedly safe suggestions for chemical stripping of cad plated components:

https://www.finishing.com/313/91.shtml

Tracking and thanks.

Posted: Tue Jul 12, 2022 6:17 pm

by RonD2

Good luck with your search.

If you search this forum on the word "cadmium" using the search feature you'll get 37 hits dating back to 2006. Maybe you already discovered them?

"Re-igniting" this thread from 2014 is also a clue.

This forum has more than 6000 members --- only a handful actively participate today.

In my opinion, most of the wisdom here is buried in more than 75,000 posts and photo albums over the last 15 years or so.

And sorting through dozens or hundreds of posts on any particular topic is always a challenge --- once you realize that many of them are left open-ended (unanswered) or ambiguous at best.

Finding the real nuggets takes perseverance and patience.

No doubt this forum is a treasure, but getting fresh answers to old questions can be difficult.

Some of the other vintage jeep forums like thecj2apage and G503 can be helpful, along with vintage car forums of any kind.

Just my 2 cents.

Good luck!