A bit of background... my son purchased this as his very first vehicle to do a restoration on. We verified the title number was matching the engine. The data plates were missing. The patent plate was present but so corroded that nothing was legible. WE found no distinguishing numbers on the frame and only found some rebuild tags on the steering box, transmission and the engine.

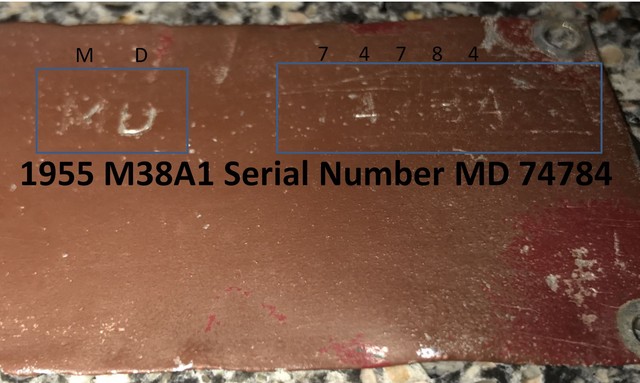

Update: I was able to gently sand the surface paint off the patent plate and I believe we have a number MD 74784 under there. I don't see any preceding 2A or anything like that. Not sure if there should be or if that was printed and not stamped?

The Willys was previously converted to 12V so we decided that the expenses of trying to re-create all the original 24V wiring, starter, generator, etc... was not economically viable.

The original tub had cancer so bad we decided to go with an aftermarket tub. By going down that path it influenced several other decisions. Upgrading to a high torque 12V starter, one wire alternator, and all modern gauges was a bit easier to swallow. If we had started with a Jeep that was closer to original then we likely would have gone down the 100% original path for the restoration. The vehicle is a compromise and we are not claiming it to be original. It's a driver and not a trailer queen.

Being a drivers vehicle the running gear was torn down and inspected. Both axles were in fairly good condition so other than a clean up and new fluids the axles were not rebuilt. The brakes however are all new from the wheel cylinders to the master cylinder.

The transfer case and transmission was completely rebuilt with NOS components and new bearings and seals. In fact we went with a front sealed bearing for the T90 to avoid the possibility of having a leak up at the front of the transmission.

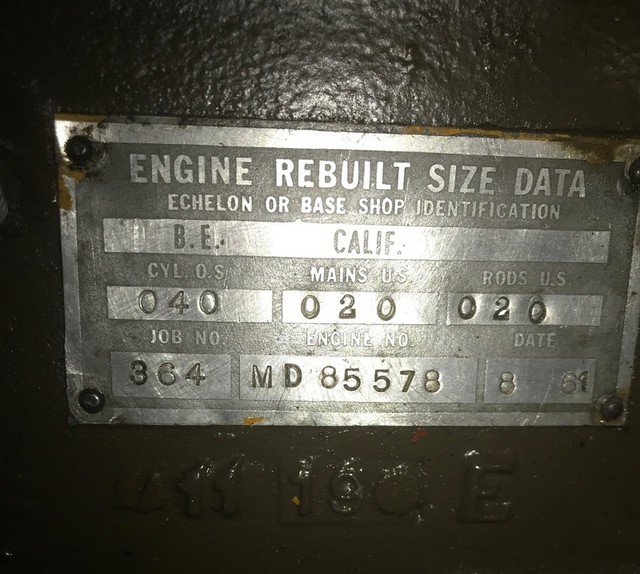

The frame was sandblasted and painted before all the rebuilt or new parts were installed. The engine was torn down and inspected but passed. It does not smoke and indicates 60 PSI while running and about 25-30PSI at idle hot. It was last rebuilt in 1961 according to the tag and I doubt it has more than a 10K or 15K miles since that rebuild. Bearings were good, pistons, etc.. cleaned up the valves and installed new seals.

We used the original style light switch and added a 24V military style turn signal switch and just used a standard 12V flasher module in place of the solid state 24V module. Works just fine. The rear tail light were changed for the Goat type lamps on both sides so we have full brake, turn, parking and black out running lights. I also added diodes and a dropping resistor for the front black out housings that were modified to accept miniature type 1157 bulbs so turn signals, running lights and even the black out lights still work up front. The front turn signal is fairly bright even with the blackout housing. Nothing like a modern vehicle but we enabled it to be functional yet look original. The trailer connector is wired for 12V and should work according to the specs. The 24V power outlet on the side of the unit obviously is now only 12V but it's functional. If anyone needs a complete 12V wiring harness schematic how it was hooked up I have one!

The vacuum fuel pump was never present on this engine so we kept the CJ5 style fuel pump that was already there. We did run some custom hard lines for the fuel as well as the PCV system. The original carburator was missing and a Solex was being used. We just recently replaced the carb with a Carter YF type. If we can find an affordable Carter YS some day then that will change. For now the YF is a significant upgrade over the small bowl Solex.

With no vacuum pump we went with inexpensive 12V electric wipers that have a park feature. They require +12V, GND, and a grounded switch. When first installed the auto park feature would not work well because the two independent wipers on the same switch would cause the wipers to only stop once they became synchronized. To avoid that issue the wiper motors were modified with a blocking diode on the PARK pin. That allows each motor to properly park with only a single switch. We used a 3 pin 90 degree Mil-Spec connector in place of the OEM vacuum valve. If we need to remove the windshield it's easy as unscrewing the connector and were in business.

Speaking of wiring... We went with more modern electrical support. A 500A master disconnect switch is in place of the original master power switch. Opted for power and ground bulkhead pass through connectors for the high current needs under-hood. A 60A fusible link was inserted on the alternator side. A waterproof fuse/relay box https://www.amazon.com/Concours-Special ... B01FWILL20 along with a master circuit breaker are installed under dash. A key switch is used for starting and ignition. All circuits are protected by fuses and any high current loads (headlights, horn, wipers, gauges, etc...) all have individual relays. A custom wiring harness ties this all together and everything is inside braided loom to make it look clean. Used modern Weatherpack connectors so we can remove the gauge cluster. Also used the same waterproof connectors up front for the lighting and each rear tail light has weatherpack connectors.

For the gauges we used Stewart Warner Heavy Duty series gauges. The Speedometer is an electrical unit that indicates upto 85MPH (yeah I tried to discourage my son going this route but he has to live with it!). The speedometer cable was replaced with a 16 pulse per revolution GM sender. The Speedometer required a calibration phase where we traveled one mile and pressed a hidden button on the unit. Now it's quite accurate and can be re-calibrated if he ever changes tires or axle ratios some day.

The fuel tank was a Bubba Mod tank that was fairly clean inside. We did coat it with some tank liner and replaced the sender, pickup and all with more modern equivalent. It works but the drivers seat is slightly elevated to clear everything due to Bubba making the tank slightly tall. Some day if an OEM tank can be found for low $$$... Yeah we can dream. The fuel runs through brass bulkhead connectors to new 3/8" hard lines. A shutoff valve replaces the original unit that was corroded badly.

It starts and runs like a new one. Some of the purists in this group will cringe at our modifications and that’s OK. This ‘55 will never be like the day it rolled off the line but this one will be driven and enjoyed none the less! Getting it registered and plated now.

My album:

http://www.willysmjeeps.com/v2/modules. ... lbum.php[u][/u]