How to time ignition on M38

Moderators: TomM, Moderator, wesk

- almis

- Member

- Posts: 2

- Joined: Sat Jan 30, 2021 6:00 pm

ignition timing on M38, no marks where it is

How to set, check the timing on a M38 from 1951?

- wesk

- Site Administrator

- Posts: 16413

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

First let us know which distributor you are using.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

- almis

- Member

- Posts: 2

- Joined: Sat Jan 30, 2021 6:00 pm

Set engine timing on a M38 with electronic distributor

Hi

I bought a M38 from U.S export to Sweden this year and the owner could never start it.

Was rebuilt to 12 volt, 2 owners backs widow said it has been working and running.

I bought in case a new electronic distributor with new cables, coil with resistor. new spark plugs. https://www.kaiserwillys.com/vehicle/50 ... 134-engine

I bought service book and sparepart book.

I read out that piston 1 is the one nearest the watercooler.

The outlet at 5 a clock is for spark piston one. I found here a article thats incorrect, at least for M38 A1!

I have no marks where I can see the timing position.

I have no wiggler. I have slide ruler/calliper to measure down to the top of the valve in spark plug hole for no 1.

How should I check and set the timing?

Thank you in advance

Bjorn Almgren

I bought a M38 from U.S export to Sweden this year and the owner could never start it.

Was rebuilt to 12 volt, 2 owners backs widow said it has been working and running.

I bought in case a new electronic distributor with new cables, coil with resistor. new spark plugs. https://www.kaiserwillys.com/vehicle/50 ... 134-engine

I bought service book and sparepart book.

I read out that piston 1 is the one nearest the watercooler.

The outlet at 5 a clock is for spark piston one. I found here a article thats incorrect, at least for M38 A1!

I have no marks where I can see the timing position.

I have no wiggler. I have slide ruler/calliper to measure down to the top of the valve in spark plug hole for no 1.

How should I check and set the timing?

Thank you in advance

Bjorn Almgren

- OKCM38CDN

- Member

- Posts: 530

- Joined: Thu Feb 16, 2012 6:00 pm

- Location: Del City, OK

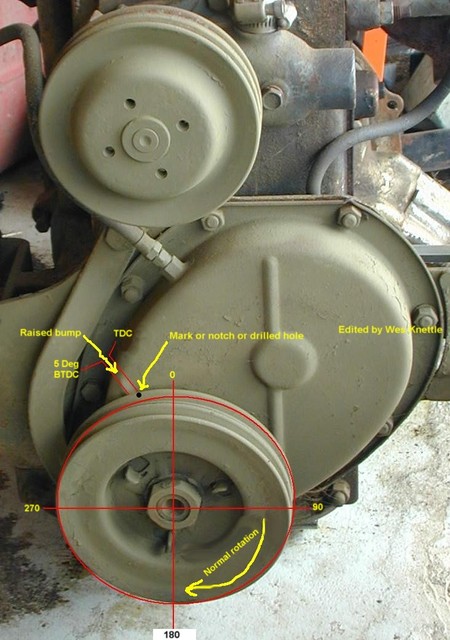

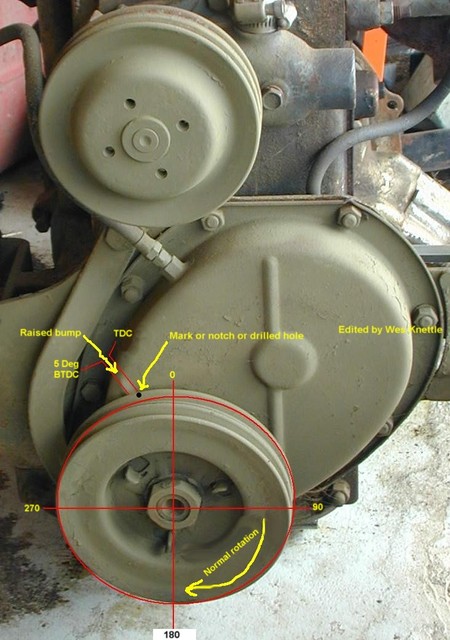

First off is to get piston #1 to 5 degrees Before top dead center (5BTDC). Easy way is on the front of the block should be timing indicator with two marks on it one is Top Dead Center (TDC) and another is 5 BTDC. The hard way is using your micrometer and measuring the top of the piston in the #1 position to TDC. Beware this position should have both valves closed so if you were to inject air into the cylinder the air will not escape, if it does you are 180 degrees off.

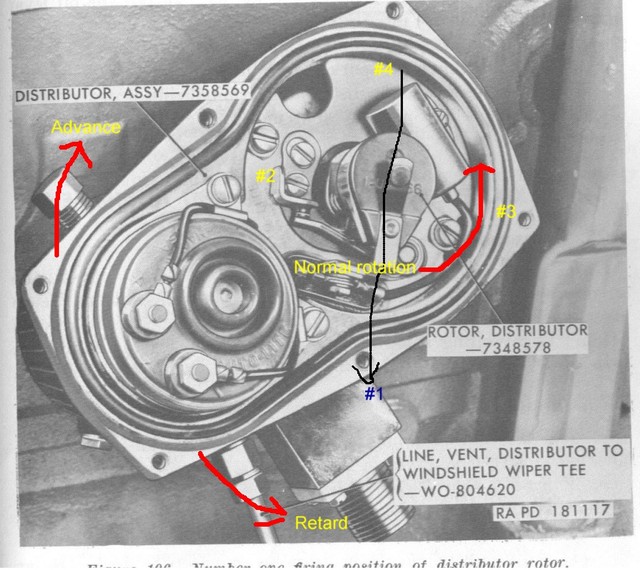

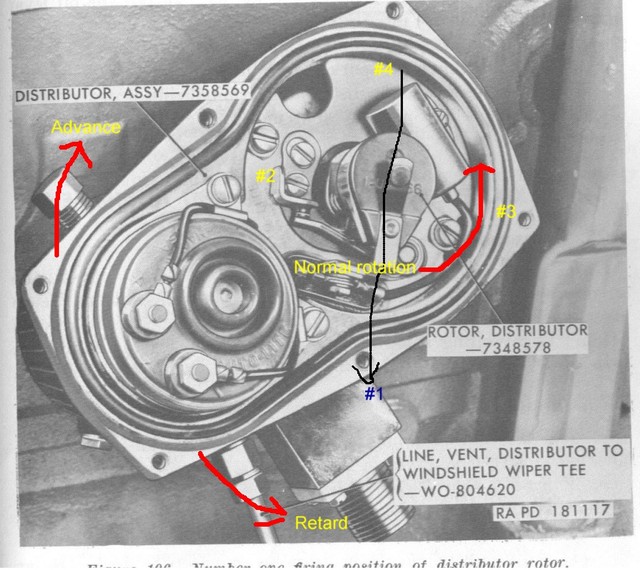

Look into the distributor slot in the block, IF the oil pump was installed correctly the view should look like the photo.

Now insert the distributor, the #1 position should be in the 7 o'clock position with the firing order 1-2-4-3. WIth you using the solid state ignition I cannot assist with that, but with standard points you set point to 0.020" gap and rotate distributor to just make /break contact with the points. Tighten The distributor and go from there.

This should work for both Military distributor and civilian distributor.

I may have left something out and I am sure I will be corrected. I just did my M-38A1 a little bit ago and it is the same procedure...

Good Luck...

Look into the distributor slot in the block, IF the oil pump was installed correctly the view should look like the photo.

Now insert the distributor, the #1 position should be in the 7 o'clock position with the firing order 1-2-4-3. WIth you using the solid state ignition I cannot assist with that, but with standard points you set point to 0.020" gap and rotate distributor to just make /break contact with the points. Tighten The distributor and go from there.

This should work for both Military distributor and civilian distributor.

I may have left something out and I am sure I will be corrected. I just did my M-38A1 a little bit ago and it is the same procedure...

Good Luck...

Hal, KB1ZQ

TSGT, USAF (Ret)

1952 M-38 CDN CAR 52-31313

1952 M-100 Strick #104

1951 Willys Wagon (For Sale)

1954 Willys M38A1 201001205

Tornado Alley

Del City, OK

TSGT, USAF (Ret)

1952 M-38 CDN CAR 52-31313

1952 M-100 Strick #104

1951 Willys Wagon (For Sale)

1954 Willys M38A1 201001205

Tornado Alley

Del City, OK

- wesk

- Site Administrator

- Posts: 16413

- Joined: Sun Apr 03, 2005 6:00 pm

- Location: Wisconsin

- Contact:

Bjorn,

Post a photo of the distributor you are using and a photo of the timing marks you are using.

Here are some examples of the photos I just mentioned:

This is a stock military distributor.

Stock m38A1 timing marks on timing gear cover.

You mention your new "Electronic Distributor" . But most of us auto technicians realize that there is no such thing for the old L134 & F134. True Electronic Ignition Systems have computers and monitor and adjust engine speeds, spark advance, manifold pressure and even fuel mixture in some applications.

So I'll assume what you are referring to is a Pertronics equipped pointless distributor that uses a Hall Effect magnetic circuit breaking system to replace the original mechanical points. These units make no improvement in performance. Their only advantage is the 2500 to 5000 mile point replacement/re-adjusting visits under the hood are not done anymore.

To help with your understanding of the distributor timing of the L134 & F134 Willys/Kaiser engines I will explain a couple of things. Unlike the earlier Willys 4 cyl. engines these two use a crank and cam timing gear set that fixes cam timing to the crack shaft timing. So basic ignition timing starts right at the front of the engine under that timing gear cover. If those timing gears are not properly set in their proper index at assembly you will not be able to attain a good ignition timing setting. Next understand that the cam drives the oil pump driven gear thru a drive gear mounted to the cam. Next understand that the oil pump drives the distributor shaft thru a slotted female recess in it's upper shaft and a matching opposite tang on the bottom end of the distributor shaft. Hence the second step in basic ignition timing is setting the oil pump driven shaft to the proper position for the distributor's shaft tang to enter. Finally rotating the upper distributor housing relative to it's shaft engagement with the oil pump will finalize the basic ignition timing.

Post a photo of the distributor you are using and a photo of the timing marks you are using.

Here are some examples of the photos I just mentioned:

This is a stock military distributor.

Stock m38A1 timing marks on timing gear cover.

You mention your new "Electronic Distributor" . But most of us auto technicians realize that there is no such thing for the old L134 & F134. True Electronic Ignition Systems have computers and monitor and adjust engine speeds, spark advance, manifold pressure and even fuel mixture in some applications.

So I'll assume what you are referring to is a Pertronics equipped pointless distributor that uses a Hall Effect magnetic circuit breaking system to replace the original mechanical points. These units make no improvement in performance. Their only advantage is the 2500 to 5000 mile point replacement/re-adjusting visits under the hood are not done anymore.

To help with your understanding of the distributor timing of the L134 & F134 Willys/Kaiser engines I will explain a couple of things. Unlike the earlier Willys 4 cyl. engines these two use a crank and cam timing gear set that fixes cam timing to the crack shaft timing. So basic ignition timing starts right at the front of the engine under that timing gear cover. If those timing gears are not properly set in their proper index at assembly you will not be able to attain a good ignition timing setting. Next understand that the cam drives the oil pump driven gear thru a drive gear mounted to the cam. Next understand that the oil pump drives the distributor shaft thru a slotted female recess in it's upper shaft and a matching opposite tang on the bottom end of the distributor shaft. Hence the second step in basic ignition timing is setting the oil pump driven shaft to the proper position for the distributor's shaft tang to enter. Finally rotating the upper distributor housing relative to it's shaft engagement with the oil pump will finalize the basic ignition timing.

Wes K

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php

45 MB, 51 M38, 54 M37, 66 M101A1, 60 CJ5, 76 DJ5D, 47Bantam T3-C & 5? M100

Mjeeps photo album: http://www.willysmjeeps.com/v2/modules. ... _album.php